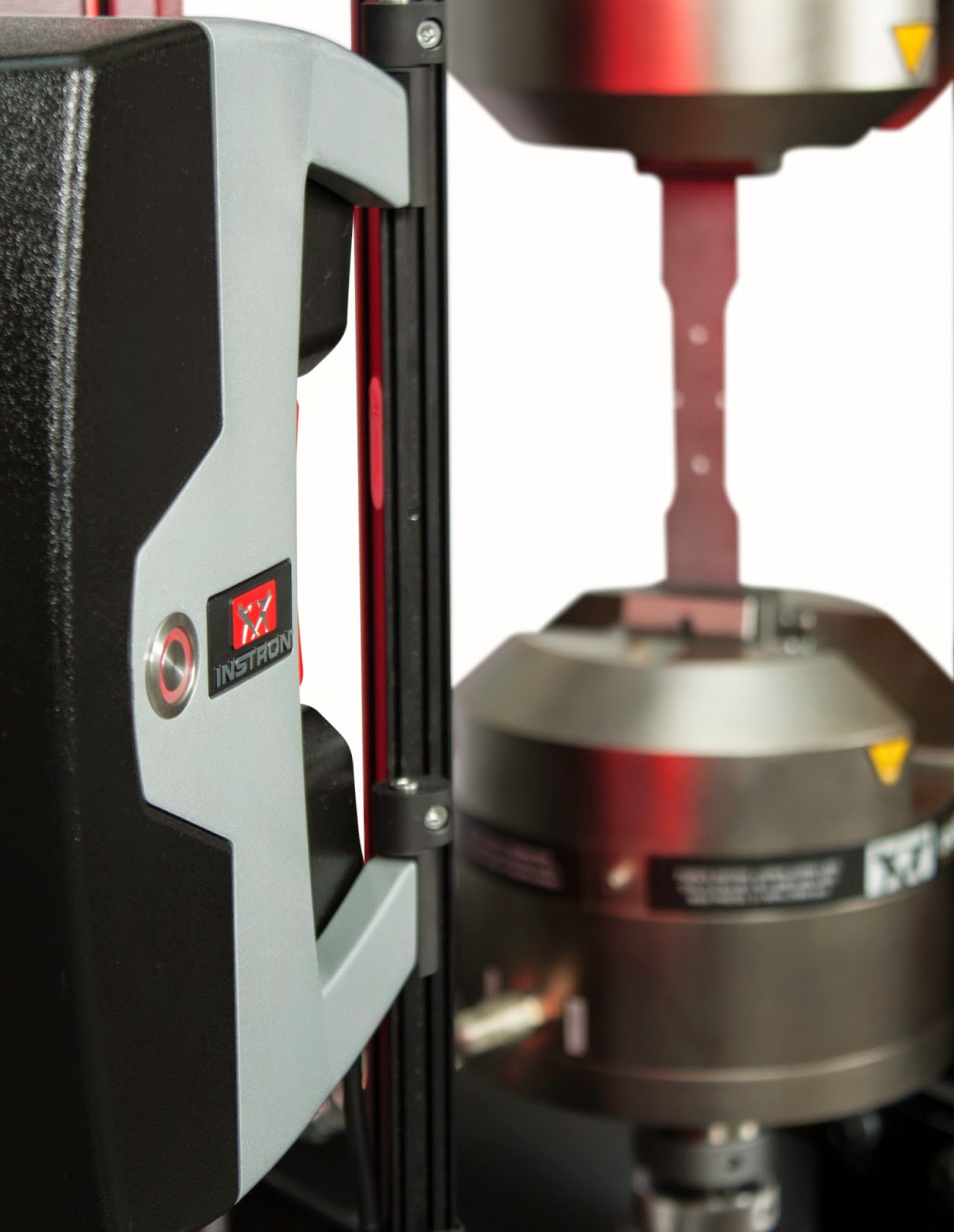

On 2nd December, Instron had the great pleasure of hosting a composites-focused masterclass for customers, based at our European Headquarters in High Wycombe, England.

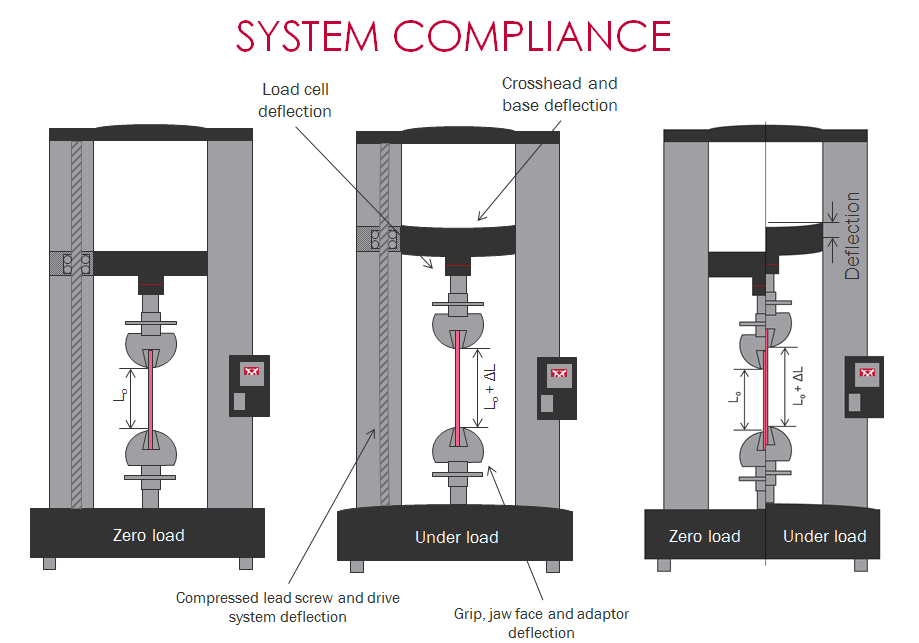

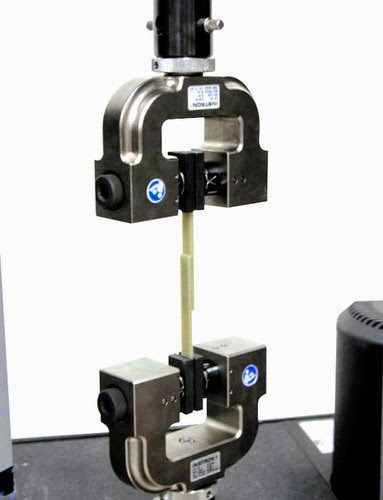

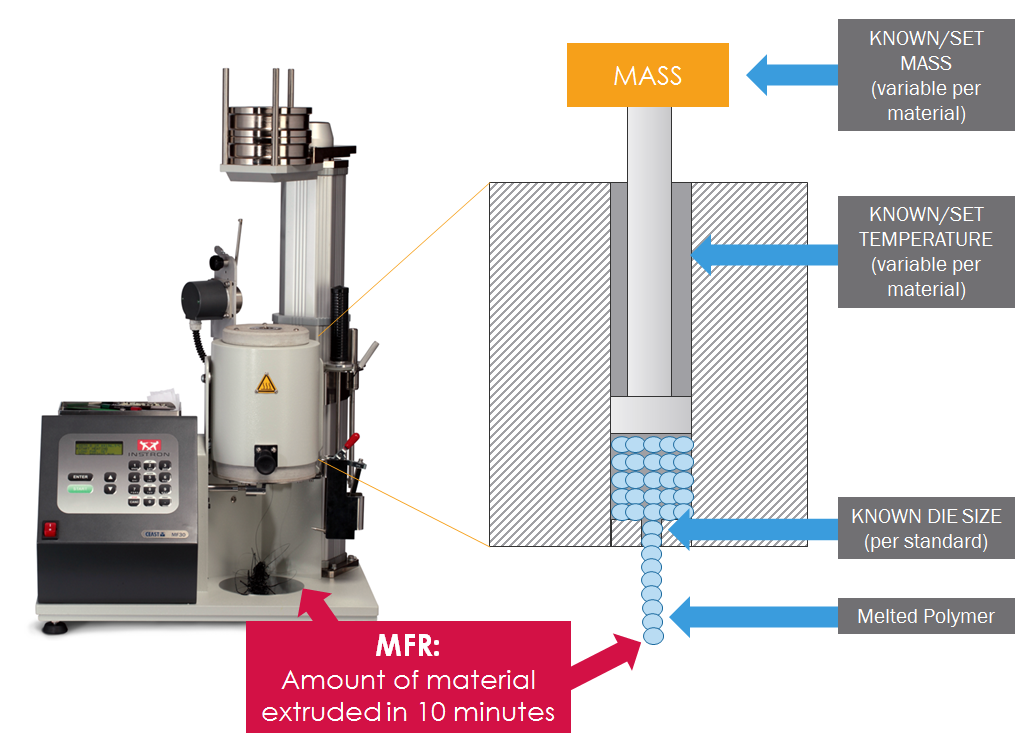

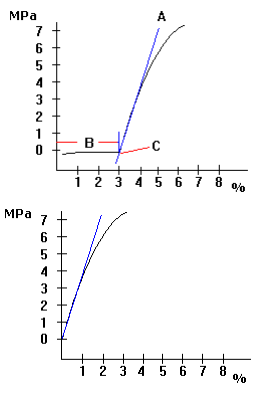

Focused around a combination of seminars and active workshops, our customers were involved in discussions surrounding a wide variety of composites-based testing challenges, from the importance of specimen alignment, to dynamic testing and advanced measurements, as well as productivity of testing and strain measurement.

We were also pleased to host Nigel O’Dea (Founder and Director of OB2B Industrial Marketing & PR) who brought with him 25 years of industry experience. His involvement and presentation reinforced the importance of the global strategic growth and challenges faced within the composites industry.

At the end of the masterclass, all customers were invited to stay on for a sneak peek around the newly vamped factory floor and had the opportunity to get hands on with a variety of demonstration machines hosted in our Applications Lab.

Overall, the masterclass proved to be an insightful look into the challenges of composites testing, and also an opportunity for great discussion between customers and our dedicated applications specialists. Here’s what one of our customers had to say about the day:

“Very well run event, all the speakers were very approachable. It totally reinforced the message that Instron is a key partner for materials testing and able to share helpful, up-to-date knowledge and insight, not just a test machine supplier.”

We will be running similar events throughout 2015; so, look out for new dates being confirmed on our website.

Read more

.jpg)